Ashley Sportiva

The 'Orrible History’

of

VNU 758

Ashley Sportiva

The 'Orrible History’

of

VNU 758

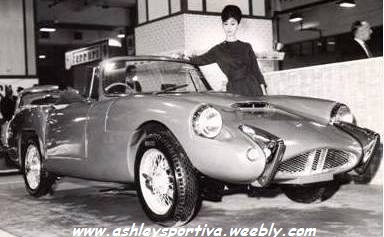

Peter Pellandine and Keith Waddington began building fiberglass kit car bodies to fit Austin 7 chassis in 1955. They worked from a garage unit next to the Robin Hood Inn in Loughton, Essex but very soon (in 1956) Pellandine left the company to start Falcon Shells - another kit car company - and a very successful one at that.

The name Ashley was chosen because "Ashleigh" was the name of Pellandine's house in Woodford Green. The company moved three times in its existence and produced the '750', the 'Sports Racer', the '1172' and the 'Sportiva' in addition to various other projects. The Sportiva retailed at £182 for the coupe body, which could be bolted to the ubiquitous Ford Pop chassis. Natural upgrades were a change to the Bellamy front end and remoting the gear lever back or finding a remote box that would fit. (The Herald one would with an adapter plate). For those with a lot more enthusiasm and a little more ‘wedge’, Ashley produced their own twin tube chassis and this was well respected in competition circles at the time.

Later in life, the Ashley tub was used as the basis for an Autocars (Israel) model and our very own first Reliant Sabre. Even though Reliant had that excellent experience and liaison with a really good fiberglass body maker, they appeared to learn nothing from it and subsequent Reliant's never did attain such a high standard of rigidity or finish.

The

Ashley 1172 body was developed by Reliant, who had acquired the rights to use and adapt it for

the basis for the Autocars (Israel) Sabra model and then their very own first Reliant Sabre range.

the basis for the Autocars (Israel) Sabra model and then their very own first Reliant Sabre range.

The Ashley Laminates Company produced a superb product for its time. Many other kit car manufacturers and some very popular main stream sports car companies never did seem to get the idea of producing panels without great waves and dishes in. Nothing on an Ashley flapped or warped - the thickness of the fiberglass was always totally appropriate for the requirement.

Probably the lightest panel was the original boot lid on both cars but the tub, bonnet and doors were as rigid as any mainstream steel car components would be. In fact, when we came to lift the tub off of our chassis we realised just how heavy it was!

The Ford Based Car

Unlike the Austin based car, my ownership of the Ford Popular based model was relatively short - that has more to with my culture of changing cars every few weeks throughout the mid 70's than any detrimental aspects of the car. Having said that, the 6-volt system inherited from the original 1930's Y Model Ford Pop was hugely unreliable although to be fair, the car was not in pristine condition.

The differences between the two cars (Ford and Austin based) was so significant as to render them totally different in every respect - other than the basic shape (although even the bonnet differed considerably).

The Austin had its Ashley bodywork 'perched upon' the Somerset chassis (but lowered as explained later). The Ford car used an Ashley twin tube chassis and the fiberglass body sat on (and in) this framework. In essence, the Ford was a far superior road holding car with its Bellamy front end and low ground clearance giving it proper sports car handling. It was 'go kart' like in its steering and suspension resulting in a car that could be literally thrown into a roundabout at ridiculous speeds and providing the 5.25 tyres could hold on - success was assured. For those old enough to remember the Ford Y chassis though (and even the later 40's Upright Pop) there was a significant and sometimes catastrophic downside of this design. In essence, one got absolutely no warning at all before the car simply flipped up on to two wheels and began to role over! The Ashley chassis I had was better - but even so, not a lot of warning was given, as I found out one evening negotiating a badly cambered roundabout a little too fast. (I was young!)

The Ford car differed in styling by having totally enclosed headlights behind Perspex covers similar to an E Type. The Austin of course had thrust forward headlamps very similar to a Ferrari of the same era!

The Austin Based Car

I don't think I'd ever heard of Ashley Laminates before being offered the coupe in early 1970. The Jensen bodied Austin A40 Sports I was using needed urgent work and had to come off the road. My dear father realised this and within a day or so suggested I go with him to a mate’s house who had an Ashley special for sale. Upon arrival at the friend’s house my eyes feasted upon - a 'hideous and very dowdy looking brown coupe type thing'. (Mother's words when she saw it later).

In any event I needed a car quickly and the more interesting and not 'run of the mill' the better. The price paid set me back half a weeks wages though - £10! My previous cars had been a Hienkel bubble car, an A30 and the A40 Sports. I think I may have had a Morris 8 Tourer at about this time too - but that was a restoration project.

An even bigger turning point in my life (other than buying the Ashley) was that I was getting married in July (1970) and I had set my heart on driving away from the church in the A40 Sports, However, this was not to be and the Ashley had to do.

Both the Austin and Ford based cars had a very similar interior having a 'flock' sprayed finish as the roof lining. Both cars deposited this 'flock' material consistently all over the place - especially if one touched it. The dash on the Austin was pure 'Somerset' and the seats were (I think) from a Ford Consul Classic or Capri. The engine was pure Somerset as well and used the standard Zenith carburetor but I later fitted the twin SU's off the A40 Sports.

The car suffered of course from any defects of the original chassis and power plant. Thankfully, the Somerset was a very rugged design and despite what is said about the British resting on their laurels, not 'keeping up' and generally producing uncompetitive products - this was the car that BMC sold to the Japanese to kick-start their full-size car programme. Up to then, the Japanese had been good at small commercials and micro-cars although they had bought the Austin Seven for development decades earlier.

According to legend and supported by a little fact - the Somerset had only one real failing and that was the Armstrong shock absorbers. Of course new they were fine but people continued to use them way after their best and this and many other Austin's 'bounced' their way around our roads of the UK, Europe, USA and Africa. For cash strapped folk like us at the time, the way to firm up the front suspension was to fill the 'shocks' with thick oil. This only lasted a short time before it completely shot the seals - but it worked for a month or so.

Apart from that (and the regulation 50's rust problems), the car would soldier on for thousands of miles with very little maintenance and lots of abuse.

I can't ever remember the Ashley letting us down at least until its final demise and that very certainly was not the cars fault - it was mine. Our first home together was a draughty, badly maintained flat in a Georgian mid terraced three-floor building. It was so damp the walls changed colour when it rained, water poured through the light fitting in the kitchen and the green carpet in the lounge gathered a white coating of mold overnight. The winter was a wet and cold one and then the snow came - and with it really cold temperatures (not the ‘sissy’ stuff we have nowadays). Stalactites formed outside shop fronts, the pavements were an icy challenge and the roads a mixture of Virgin snow - or highly polished ice in deep tracks. Because I used the car every day and very often quite late at night, I had previously been very lucky with regards to engine and radiator water. On the first of the real 'freezing nights' I had not used the car late - and the weather beat me. When I came to start her up early next morning, I had no joy at all and upon close inspection she had blown at least four core plugs - including the one at the back of the engine up against the bulkhead. So that was that!

As usual I needed transport urgently so it was easier to talk to my brother in law and get another car by the end of the day than contemplate repairs to the old faithful. I think the replacement may have been an upright Ford Pop - about a 'fiver's' worth.

The Ashley went to park up alongside the Jensen at Dad's place (thankfully he had plenty of room).

There it languished under a tarpaulin for about 20 years.

Children, houses and motor homes took priority but eventually we bought a house with enough room for a large double garage and attached workshop. Once built, we installed the Jensen and the Ashley. The Jensen was 'put on ice' whilst the Ashley was attacked with some vigour.

VNU

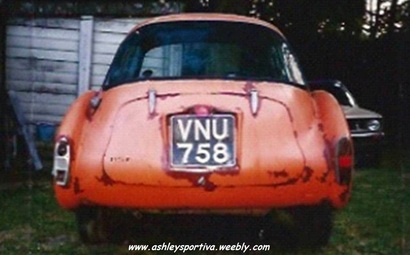

Looking Very Sad After 30 Years VNU with

Bonnet Removed

or More of Neglect.

My eldest son was still at school initially but after a short time joined a Fiat dealership and began his life in cars. However, after a couple of months, we got him into a Vintage car restoration workshop where he stayed for 18 years before starting his own business on the 1st January 2009. On his website (thornleykelham.co.uk) he refers to this car and the A40 Sports - and how he used to work on them after school.

(If you love cars, this website is a feast of automotive beauty).

In retrospect, we should perhaps of left the Ashley as a coupe. A really good one has been advertised in Holland for over £20,000 but whether it sold at that figure I have no idea (I doubt it). Certainly at the time - about 20 years ago - old kit cars were not respected as they are today. Today they are regular contenders on the Brooklands Test Hill but 20 years ago these cars were considered the lowest of the low.

or More of Neglect.

My eldest son was still at school initially but after a short time joined a Fiat dealership and began his life in cars. However, after a couple of months, we got him into a Vintage car restoration workshop where he stayed for 18 years before starting his own business on the 1st January 2009. On his website (thornleykelham.co.uk) he refers to this car and the A40 Sports - and how he used to work on them after school.

(If you love cars, this website is a feast of automotive beauty).

In retrospect, we should perhaps of left the Ashley as a coupe. A really good one has been advertised in Holland for over £20,000 but whether it sold at that figure I have no idea (I doubt it). Certainly at the time - about 20 years ago - old kit cars were not respected as they are today. Today they are regular contenders on the Brooklands Test Hill but 20 years ago these cars were considered the lowest of the low.

A Not Unattractive Rear End ?

A Not Unattractive Rear End ?

Our

plan then was to rid the car of its rather ungainly coupe shape and having

removed the roof and screen (it was the screen shape that was really ugly - in

our view) give the car a Triumph Spitfire windscreen and a sloping rear panel

with the spare wheel laid on it.

Topless – and Not Very Pretty !

Topless – and Not Very Pretty !

Once the body was off we began the laborious task of stripping the chassis and rebuilding it with new brake lines, linkages, major components etc. About two months into the work a dreadful fact became evident.

The chassis, instead of being a good, stout and heavy Austin frame was as thin as tissue paper in places. We had started welding in some new parts and fabrications but it was a never-ending battle. What we needed was a new (relative term of course) chassis.

The chassis, instead of being a good, stout and heavy Austin frame was as thin as tissue paper in places. We had started welding in some new parts and fabrications but it was a never-ending battle. What we needed was a new (relative term of course) chassis.

Off With Her Body ! A Better Rear End.

Within a few weeks we were offered a complete Somerset that a gentleman in the media industry had bought for his son - but his son was not thus inclined.

We paid £80 for the car and then had the extraordinary task of retrieving it from under a building and through two gateposts with about half an inch of clearance either side.

It took some time but eventually it was on the trailer and on its way home - which thankfully was only a few miles.

We had added lots of work to the program of course and deadline-finishing dates disappeared faster than a politicians promise. We now had to strip the body off the new chassis and with all good intentions of restoring the relatively sound panels that could be used by other Austin Counties Club members at a later date.

Eventually, with the body removed we could see that the new chassis was as sound as could be - virtually no rust anywhere and probably three or four times the thickness of our original car's.

We paid £80 for the car and then had the extraordinary task of retrieving it from under a building and through two gateposts with about half an inch of clearance either side.

It took some time but eventually it was on the trailer and on its way home - which thankfully was only a few miles.

We had added lots of work to the program of course and deadline-finishing dates disappeared faster than a politicians promise. We now had to strip the body off the new chassis and with all good intentions of restoring the relatively sound panels that could be used by other Austin Counties Club members at a later date.

Eventually, with the body removed we could see that the new chassis was as sound as could be - virtually no rust anywhere and probably three or four times the thickness of our original car's.

My son's influence on this project was considerable. By now he was at the Vintage restoration company and his standards had gone through the roof. No longer was the term 'good enough' good enough! Now we were constructing a car that was going to be built and finished to the highest standards humanely possible. The chassis was finished to a very high standard and then painted in cellulose Post Office Red - many, many coats of it. The finished work was then polished - many times! We were mindful of the fact that a fiberglass bodied Jensen had won the concourse car title at the NEC Classic Car Show that year. We had visited the show and my son had seen the winning car. In his view - we could do better!

The Spitfire Screen Sitting so Well.

The Spitfire Screen Sitting so Well.

I acquired the Triumph Spitfire windscreen and surround from a Triumph enthusiast work colleague.

Grafting the Spitfire windscreen on to the tub once the original fiberglass frame (as part of the roof) had been removed was extraordinarily easy.

Later in our research, the reason became evident. It would appear that the Reliant Sabre used the same (or very similar) screen as we had adopted. The Sabre of course used the Ashley tub but with its own style of front and rear treatment.

Grafting the Spitfire windscreen on to the tub once the original fiberglass frame (as part of the roof) had been removed was extraordinarily easy.

Later in our research, the reason became evident. It would appear that the Reliant Sabre used the same (or very similar) screen as we had adopted. The Sabre of course used the Ashley tub but with its own style of front and rear treatment.

The New Fabricated Rear Seat (Single on the Nearside) and Foot Well.

The New Fabricated Rear Seat (Single on the Nearside) and Foot Well.

One of the things we were dedicated to achieving was lowering the body on the chassis. In its original form, the car was too high off the ground - rather like an E Type jacked up by about twelve inches - it didn't help the appearance at all!

Lowering the suspension was a possibility but whilst the front was easy to do by shortening the coil springs the rear was harder. One would think it was easy to do by 'under slinging' the rear axel but there was just not enough room between the top of the axel and the lower part of the chassis. No doubt we could have fitted longer shackles or something but we decided against it at the time.

Lowering the suspension was a possibility but whilst the front was easy to do by shortening the coil springs the rear was harder. One would think it was easy to do by 'under slinging' the rear axel but there was just not enough room between the top of the axel and the lower part of the chassis. No doubt we could have fitted longer shackles or something but we decided against it at the time.

Once the chassis had its umpteen coats of Post Office Red cellulose and been scratch filled and re-painted again and again, the polished chassis was carefully introduced to its tub - albeit with the back section completely missing - everything taken away that would not be required with our new sloping back end.

Some of the Floor Components Laid Out on the Drive

Some of the Floor Components Laid Out on the Drive

This was the really tricky part because we then began to mark out where the chassis members were and cut the body away to fit around them - thus sinking the chassis a good six inches into the tub.

The next stage was to fabricate the plywood floor around the chassis in such a way as to still be able to get ones feet to the pedals. The photograph of the unassembled floor laid out on the drive gives some idea of the complexity if this.

The next stage was to fabricate the plywood floor around the chassis in such a way as to still be able to get ones feet to the pedals. The photograph of the unassembled floor laid out on the drive gives some idea of the complexity if this.

Meanwhile the engine - having decided to keep the original 1200cc Austin Somerset engine but fit the upgraded Somerset head with its twin SU's - was completely rebuilt. The crank was in good condition as were the pistons so we simply fitted new mains, shells, little ends and rings. Externally the engine received a lot if attention to the paint finish.

Some years before I had 'remoted' the gearbox by using a couple of ball joints, a made up cradle front and rear and a long rod. All this went back virtually as it was. It worked well and was heaps better than a lever sprouting out the gearbox and travelling back to the driver in near horizontal position meaning third was rammed under the dash and fourth was lying on the floor!

Returning to the bodywork, Wayne acquired the aluminum and some 1" square section steel tubing for the framework at the rear. We began to fabricate a steel frame from the one-inch square section tube so that our almost flat aluminum panel carrying the (very heavy) spare wheel would be rigid enough. Access to the boot would be via the interior - i.e. no boot lid. We were going to use the Jensen A40 Sports wheels and one of these on the rear panel looked most attractive. The 'Jensen' wheel had multiple elongated holes rather than the very heavy slotted wheels of the Somerset range.

Some years before I had 'remoted' the gearbox by using a couple of ball joints, a made up cradle front and rear and a long rod. All this went back virtually as it was. It worked well and was heaps better than a lever sprouting out the gearbox and travelling back to the driver in near horizontal position meaning third was rammed under the dash and fourth was lying on the floor!

Returning to the bodywork, Wayne acquired the aluminum and some 1" square section steel tubing for the framework at the rear. We began to fabricate a steel frame from the one-inch square section tube so that our almost flat aluminum panel carrying the (very heavy) spare wheel would be rigid enough. Access to the boot would be via the interior - i.e. no boot lid. We were going to use the Jensen A40 Sports wheels and one of these on the rear panel looked most attractive. The 'Jensen' wheel had multiple elongated holes rather than the very heavy slotted wheels of the Somerset range.

The Dashboard Trim and Central Switches Take Shape

The Dashboard Trim and Central Switches Take Shape

Once the engine and gearbox was in and the body on - complete with its multi - component floor, we could begin the trimming. We had had a new wiring harness made up and were fitting either new or very good lights and gauges. We had planned to use small bucket seats similar to an MG of the 30's.

We now had a really attractive looking soft-top car with its long sweeping bonnet with thrust forward headlamps and distinctive shaped grill. We had fitted 'reverse gull wing doors' doors hinged at the lower edge, similar to some sports racers of the 50's.

Because the doors were quite shallow (obviously with no glass or frame attached), it was easy to step in and out of the car. I had fabricated some shortened seat belts to allow the doors to 'fall' under control and lock in the down position.

Because the doors were quite shallow (obviously with no glass or frame attached), it was easy to step in and out of the car. I had fabricated some shortened seat belts to allow the doors to 'fall' under control and lock in the down position.

The New Screen Fitted and the Wings Shaping Up

The New Screen Fitted and the Wings Shaping Up

We then started to trim the car with aluminum where it would improve the appearance and reduce the 'kit-car' look. The doorsteps and the bulkhead were first for attention - and the polished aluminum finish to this area particularly was a great improvement over the fiberglass original.

Getting The Body Finish We Wanted

Getting The Body Finish We Wanted

Finally the car was finished in 'show and tell' beige colour and we began the task of getting 'the worlds best kit car' finish we were after.

And then we moved house!

The rationale was that the family had all left home and the drive no longer needed to house a 21ft Cadillac, Dodge step-side truck, Humber Sceptre (V8 Daimler), A40 Sports, Dutton Phaeton, Ford Thames custom van (V8 Ford), VW Bay Window camper, Renault 5 and - a Marina.

We moved to a small 1800's cottage with a single garage and workshop and drive for one car. Big mistake obviously - yes, I see that now!

Actually the garage was a fair size and the completion of the rebuild would not be a problem - except that the cottage would need three years work (actually ten) to get to be what we wanted. Needless to say the Ashley went into storage in a friends barn about 15 miles from home and the 'Jensen' went to a collector in the Forest of Dean. I bought a 109 Land Rover and 'Project Cottage' began.

The barn housing the Ashley was on an old disused farm - owned by a very good friend of mine. The barn also housed a Lightweight Land Rover belonging to another chap - and hundreds of bits of office furniture, shelving, cabinets etc. these items had just been collected in the line of his business - facilities management.

My friend and I saw each other regularly for the first few years and I went down and looked at the Ashley every few months or so. Then, I was made redundant and started our business so that I had very little contact with my friend.

After about five years of running the business, I was acutely aware of the need to thank my friend for looking after my car all this time - about ten years in total. Re-enacting some old times we invited them to our mutually favourite restaurant for an evening meal.

At some point I made it known that we would be picking up the 'tab' as a token thank you for storing the Ashley all this time. Further more, we planned to come and get it - the restoration was to be completed.

At this point, my friend went a strange ashen colour and with strangled voice told us that he had forgotten all about our car! Upon investigating further it was evident that he had not been down to the barn for years but had recently rented it out to some travellers on the understanding they cleared the contents!

In fairness to him, he is a very wealthy man who owns various properties and as he himself said, "I haven't been down to the barn for years!"

My friend did go the barn the very next day though - and the car had gone.

And that you might think was the end of that.

But no!

Some months later, I received a phone call from my daughter. She and her partner were scavenging about a nearby scrapyard looking for bits for one of their cars (my daughter had a fondness for 1970’s Viva's) when they came across a wreck some way away from the piles of 80's and 90's Euro boxes.

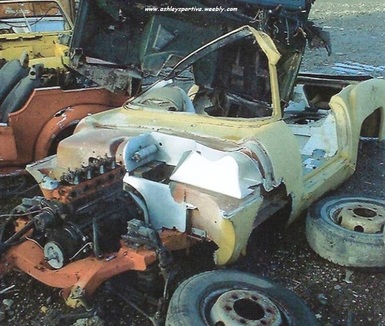

The Thing on Top is the Lightweight Land Rover!

The Thing on Top is the Lightweight Land Rover!

I

drove straight to the yard and armed with the logbook, original bill of sale

and umpteen photographs, spoke to the man in the office.

I gave him the story and when he saw the pictures of the work that had gone into the car now in his yard, he was actually mortified.

He could not apologize enough - although in essence it was not his fault at all.

I gave him the story and when he saw the pictures of the work that had gone into the car now in his yard, he was actually mortified.

He could not apologize enough - although in essence it was not his fault at all.

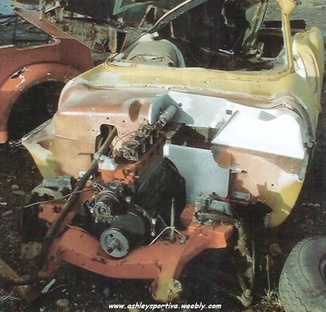

The Spitfire Screen Doesn’t Seem To Fit So Well Anymore.

The Spitfire Screen Doesn’t Seem To Fit So Well Anymore.

Scurrying over to the car, all the time telling anyone who would listen that I was not leaving without it I finally came upon the sorry sight. Within minutes it was evident that I had been naïvely and hugely optimistic. To be honest, nothing that had happened to the body would have put me off. In the worst-case scenario, I would have taken all the Ashley bits off and built my own body from ply, timber and ally.

But the chassis was the problem. The 'grabber' had grabbed it not just at either 'sill' - side rails - but also apparently on one side rail and one rear corner. The chances of the chassis not being twisted were remote. The (very rare) Jensen wheels had gone, the engine was seized and the whole thing was in the most sorry state.

But the chassis was the problem. The 'grabber' had grabbed it not just at either 'sill' - side rails - but also apparently on one side rail and one rear corner. The chances of the chassis not being twisted were remote. The (very rare) Jensen wheels had gone, the engine was seized and the whole thing was in the most sorry state.

The doors seem to have gone astray also

The doors seem to have gone astray also

Blokes aren't supposed to cry but I came darned close as I turned my back on hundreds of hours work for my son and myself - and over 30 years of ownership.

The really annoying thing?

I should have kept a closer eye

on it!

I have no one else to blame but myself!

THE END

Many thanks to Martyn Kelham for his story

I think we can now consider this Ashley Sportiva as as a non-survivor